Do you have any questions?

Direct consulting

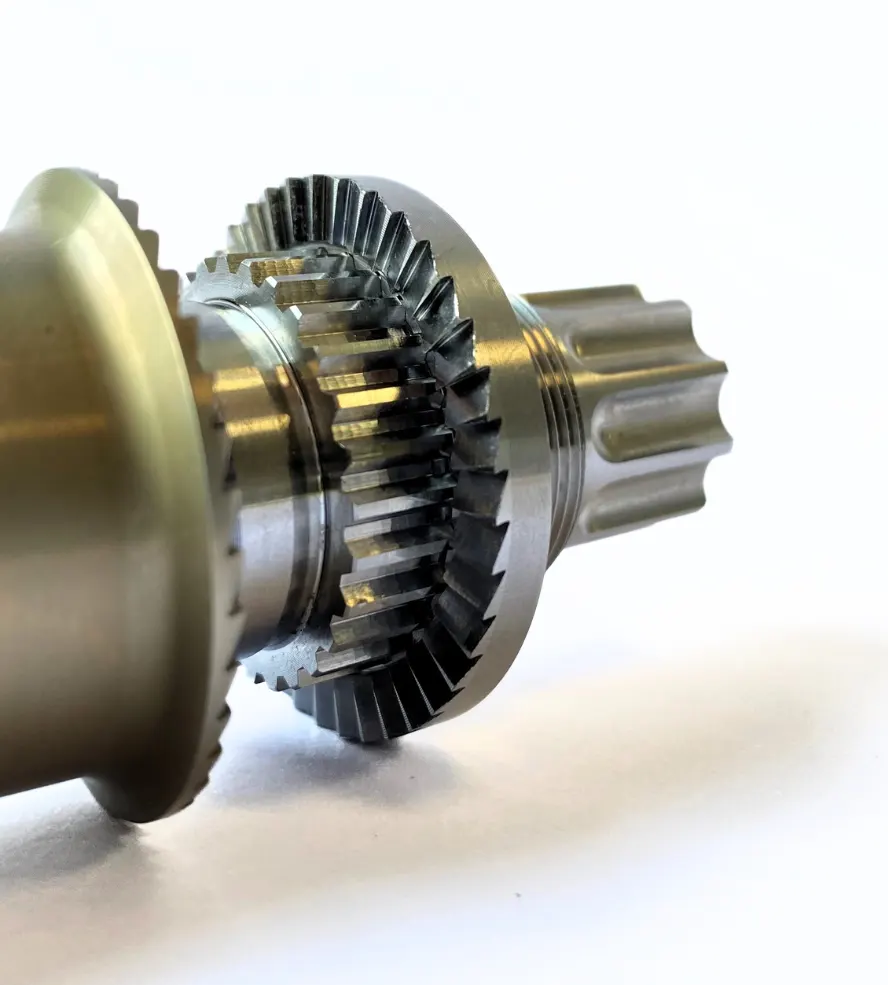

Straight toothing

Your partner from development to series production

Quality made in Germany

- High gear cutting accuracy in accordance with DIN 3962

- CNC-automated series production

- Measurement for tested dimensional and flank accuracy

- Versatile materials from steel to plastic

Automated production

Maximum efficiency thanks to fully automated CNC processes.

Precision parts

Series parts for drive systems and e-mobility.

System provider

Complete solutions thanks to Group expertise.

IATF quality

Certified processes ensure automotive standards.

Precise production for high-performance spur gears

We manufacture spur gears with maximum dimensional accuracy and reproducible quality - from individual gears to complex gear stages. Our CNC-controlled machining centers enable the production of involute gears with a defined tooth module, optimum backlash and excellent surface quality.

Using state-of-the-art gear cutting technologies such as hobbing, power skiving and profile milling, we achieve cost-effective production processes and consistent gear quality in accordance with DIN 3962.

Using state-of-the-art gear cutting technologies such as hobbing, power skiving and profile milling, we achieve cost-effective production processes and consistent gear quality in accordance with DIN 3962.

Our services in spur gearing

- Production of internal and external gears up to module 10

- Power skiving and hobbing for precise cylindrical gear profiles

- Production of gear pairings with documented flank correction

- Grinding of the tooth flanks for smooth running

- Measurement reports with 3D gear analysis in accordance with DIN ISO 1328

- Prototype and series production in one continuous process

- Automation and 100% inspection for consistent gear quality

Process stability and quality thanks to modern spur gear technology

Our many years of experience in gear production combined with automated production cells ensure maximum process stability.

By using multi-channel CNC controls, integrated measurement technology and closed-loop process control, we guarantee consistent quality - from sample production to mass production. All spur gears are manufactured in accordance with ISO 9001 and IATF 16949 and validated by our metrological final inspection.

By using multi-channel CNC controls, integrated measurement technology and closed-loop process control, we guarantee consistent quality - from sample production to mass production. All spur gears are manufactured in accordance with ISO 9001 and IATF 16949 and validated by our metrological final inspection.

Variety of materials for our spur gear solutions

We manufacture spur gears from a wide range of metallic and technical materials. Each material group is selected according to load profile, torque requirement and wear behavior.

Our material expertise:

We achieve maximum hardness, smooth running and service life through targeted heat treatment and fine grinding of the tooth flanks.

Our material expertise:

- Case-hardening steels and heat-treatable steels for highly stressed tooth flanks

- Stainless steels for corrosion-resistant gear components

- Aluminum and non-ferrous metal gears for lightweight applications

- High-performance plastics for low-noise, maintenance-free solutions

We achieve maximum hardness, smooth running and service life through targeted heat treatment and fine grinding of the tooth flanks.

| Material group | Typical qualities / alloys | |

|---|---|---|

| Steels & stainless steels | 16MnCr5, 42CrMo4, 1.4301, 1.7225 | |

| Non-ferrous metals | Brass CuZn39Pb3, bronze, copper | |

| Aluminum alloys | EN AW-6082, EN AW-7075 | |

| Plastics & special materials | POM, PEEK, titanium grade 5 | |

CNC-controlled production systems for spur gears at the highest level

Our production uses state-of-the-art CNC machining centers with automatic workpiece feed and digital process control.

From CAD/CAM-based tooth geometry development to metrological final inspection, all process steps are fully digitally networked.

Our measuring systems record parameters such as tooth flank profile, pitch circle diameter and concentricity in real time.

This enables us to guarantee maximum dimensional accuracy, reproducibility and efficiency - with maximum vertical integration.

From CAD/CAM-based tooth geometry development to metrological final inspection, all process steps are fully digitally networked.

Our measuring systems record parameters such as tooth flank profile, pitch circle diameter and concentricity in real time.

This enables us to guarantee maximum dimensional accuracy, reproducibility and efficiency - with maximum vertical integration.

Spur gearing for mechanical engineering and drive technology

Our spur gears are used in numerous branches of industry where torque transmission, low noise and durability are crucial.

Application examples:

We support our customers from design to series production and offer material- and production-optimized solutions for every application.

Application examples:

- Automotive and e-mobility: gear stages, axle drives, steering mechanisms

- Mechanical and plant engineering: couplings, drive shafts, conveyor technology

- Robotics & automation: planetary gears, servo drives, actuators

- Precision mechanics & medical technology: precision gears, micro drives

- Energy and environmental technology: pumps, generators, compressors

We support our customers from design to series production and offer material- and production-optimized solutions for every application.

Contact us

We look forward to hearing from you. Find out more about the extensive development and production options we can offer you.

Address

Enno-Heidebroek-Strasse 7 01237 Dresden Germany

Always precise. Always competent. Always solution-oriented.

Become a partner of a European group of companies. Choose Präzisionsteile Dresden and the KAP Precision Components group of companies.

Become a partner of a European group of companies. Choose Präzisionsteile Dresden and the KAP Precision Components group of companies.

Request

Frequently asked questions on the topic: