Do you have any questions?

Direct consulting

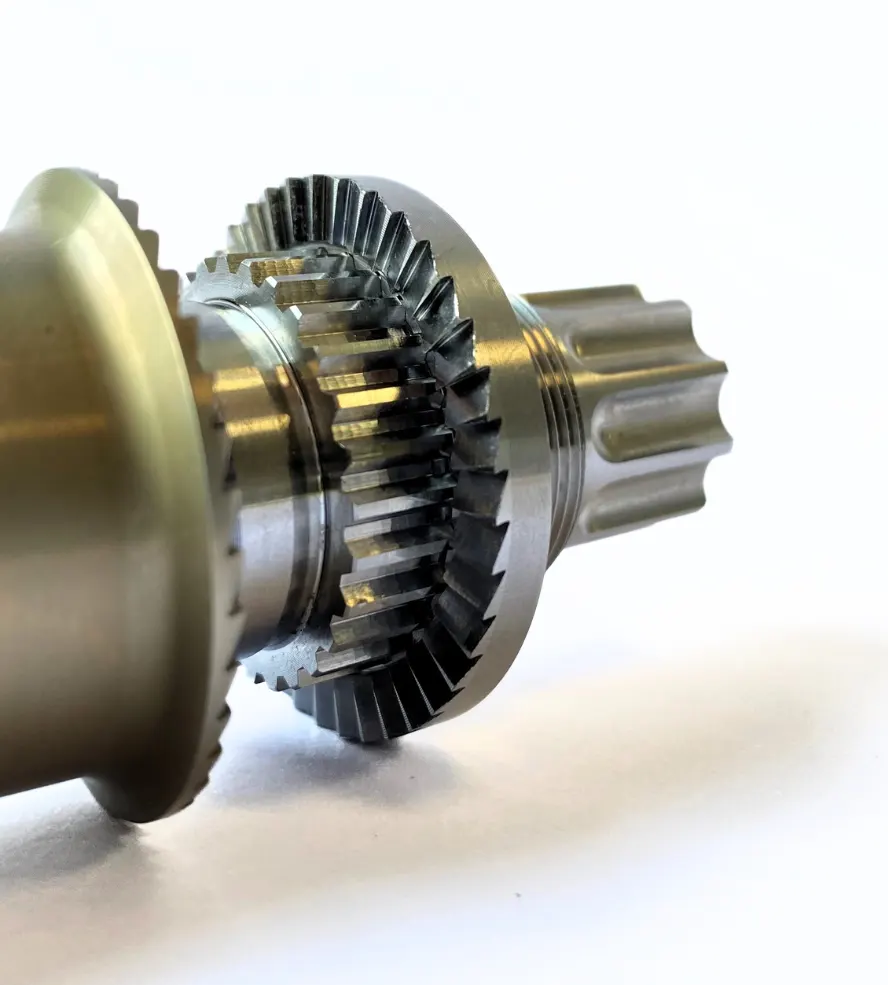

Internal gearing

Your partner from development to series production

Quality made in Germany

- Precise internal gearing with power skiving and splines.

- Series quality thanks to automated inline measurement.

- Versatile materials for every application.

- Certified production in accordance with ISO 9001 / IATF 16949.

Automated production

Maximum efficiency thanks to fully automated CNC processes.

Precision parts

Series parts for drive systems and e-mobility.

System provider

Complete solutions thanks to Group expertise.

IATF quality

Certified processes ensure automotive standards.

Technological excellence in the production of internal gears

We are a manufacturer of high-quality internal gears that are used in a wide variety of drive systems, clutches and transmission components.

Our company provides support from production-oriented product design to metrological quality assurance.

Thanks to state-of-the-art processes such as power skiving, spline cutting and hobbing, we achieve maximum dimensional accuracy, accuracy of fit and flank accuracy - even for complex involute or serrated gears in accordance with DIN 5480 / DIN 3962.

Our company provides support from production-oriented product design to metrological quality assurance.

Thanks to state-of-the-art processes such as power skiving, spline cutting and hobbing, we achieve maximum dimensional accuracy, accuracy of fit and flank accuracy - even for complex involute or serrated gears in accordance with DIN 5480 / DIN 3962.

Our services in internal gearing

- CNC-supported production of internal gears in module ranges from 0.3 to 8

- Power skiving for high efficiency with internal and external profiles

- Splines for deep or difficult-to-access geometries

- Hard fine machining and gear grinding for the highest surface quality

- Metrological testing of every gear with documented quality in accordance with ISO 1328

- Prototype and series production on highly automated production lines

- Design & CAD support for individual gear cutting processes

Innovative internal gearing through experience, technology and quality assurance

With decades of experience in precision gearing, we combine technical expertise, automated process control and quality-assured production.

Our modern CNC shaping machines and power skiving systems enable short cycle times with consistently high tolerance accuracy.

Inline measuring systems permanently monitor the profile and flank quality in order to correct dimensional deviations immediately.

This results in internal gears that guarantee durable and backlash-free power transmission even at high torques.

Our modern CNC shaping machines and power skiving systems enable short cycle times with consistently high tolerance accuracy.

Inline measuring systems permanently monitor the profile and flank quality in order to correct dimensional deviations immediately.

This results in internal gears that guarantee durable and backlash-free power transmission even at high torques.

Production portfolio and material expertise for internal gears

We manufacture our internal gears from a wide range of materials - tailored to load, torque, temperature resistance and corrosion requirements.

Thanks to optimum cutting data, cooling strategies and tool geometries, we achieve process-reliable production down to a surface roughness of Ra 0.8 µm.

Advantages:

Thanks to optimum cutting data, cooling strategies and tool geometries, we achieve process-reliable production down to a surface roughness of Ra 0.8 µm.

Advantages:

- Optimized material selection for specific application conditions

- Combination of machining, heat treatment and fine machining

- Long tool life thanks to adapted tool parameters

- Long-term dimensional accuracy, even for large series

| Material group | Typical alloys / qualities | |

|---|---|---|

| Steels & stainless steels | 1.0503 (C45), 1.7225 (42CrMo4), 1.4301, 1.4112 | |

| Aluminum alloys | EN AW-6082, EN AW-7075 | |

| Non-ferrous metals | CuZn39Pb3, bronze, nickel alloys | |

| Plastics / special materials | POM, PEEK, titanium grade 5, Inconel 718 | |

Internal gears from automated high-tech production

Our production combines digital process control, predictive maintenance and closed-loop gearing technology, which enables continuously monitored and self-optimizing production. CAM-based programming (e.g. Inventor, Esprit) enables even complex tooth profiles to be manufactured efficiently, precisely and reproducibly.

Hydrostatic guides, multi-channel controls and temperature-compensated machine frames ensure micrometer-precise gearing quality.

From prototype to mass production.

Hydrostatic guides, multi-channel controls and temperature-compensated machine frames ensure micrometer-precise gearing quality.

From prototype to mass production.

Internal gearing for industry, mechanical engineering and e-mobility

Our internal gears are used wherever torque transmission, zero backlash and wear resistance are crucial. We cover numerous fields of application in modern drive technology thanks to our wide range of materials and production methods.

Typical areas of application:

Our optimized production guarantees consistent quality, short delivery times and maximum process stability - even for complex series orders.

Typical areas of application:

- E-mobility & automotive: transmission components, clutch elements, differentials

- Mechanical engineering & robotics: shaft connections, precision couplings

- Aerospace: lightweight gears made from aluminum or titanium

- Energy & wind technology: internal gears in planetary stages

- Medical technology & precision mechanics: Miniaturized tooth profiles with high running smoothness

Our optimized production guarantees consistent quality, short delivery times and maximum process stability - even for complex series orders.

Contact us

We look forward to hearing from you. Find out more about the extensive development and production options we can offer you.

Address

Enno-Heidebroek-Strasse 7 01237 Dresden Germany

Always precise. Always competent. Always solution-oriented.

Become a partner of a European group of companies. Choose Präzisionsteile Dresden and the KAP Precision Components group of companies.

Become a partner of a European group of companies. Choose Präzisionsteile Dresden and the KAP Precision Components group of companies.

Request

Frequently asked questions on the topic: